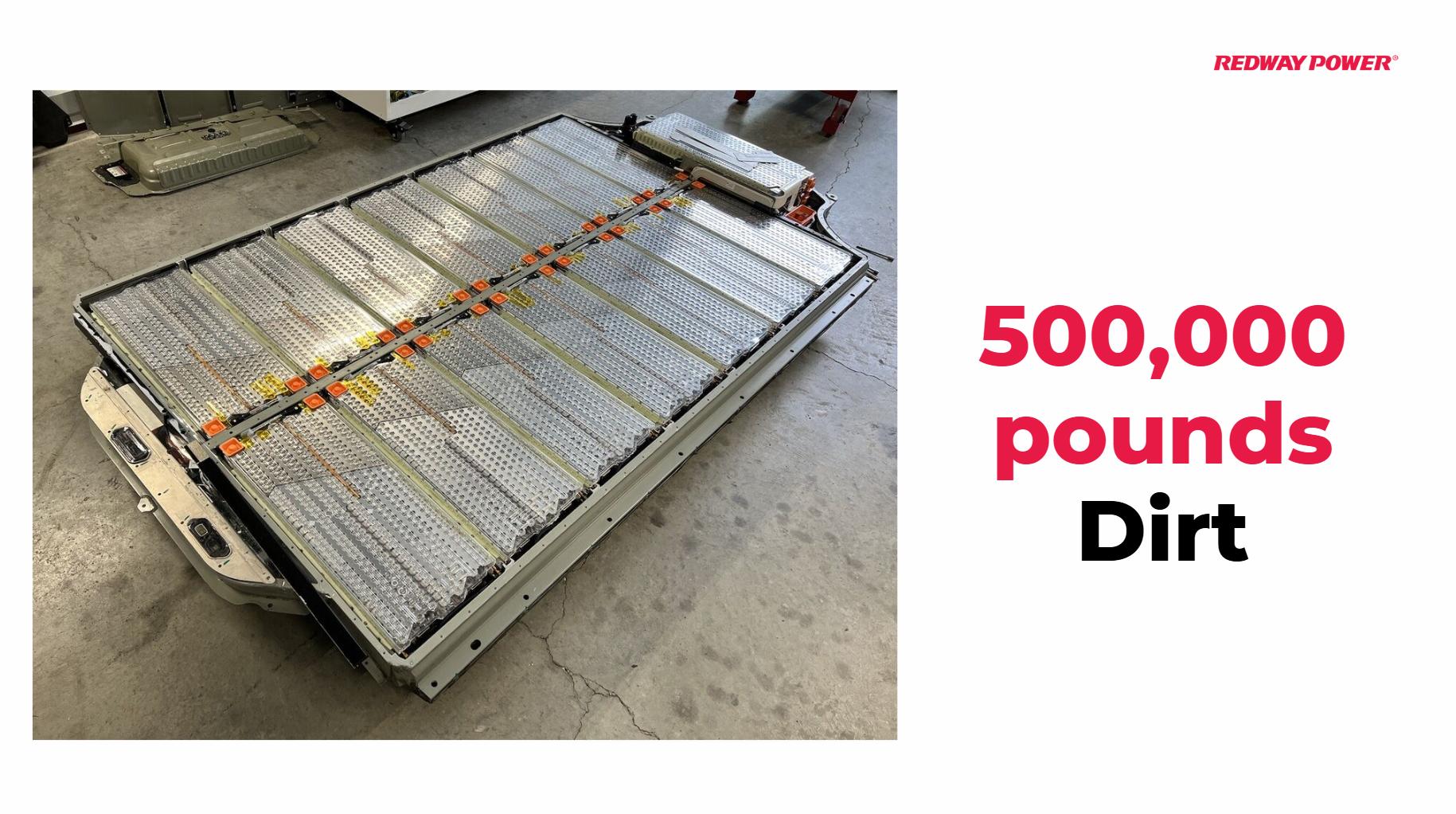

How Much Dirt Is Moved to Make a Tesla Battery?

Making a Tesla battery requires moving significant amounts of earth during the mining of raw materials like lithium, cobalt, and nickel. The extraction process involves large-scale mining operations that impact ecosystems and consume vast volumes of water and energy. While exact quantities vary by location and mining method, thousands of tons of dirt and rock are moved to extract the materials needed for a single battery pack. Responsible sourcing and recycling efforts, championed by industry leaders like Lithium-Battery-Manufacturer, help mitigate these environmental effects.

What raw materials are mined to produce Tesla batteries?

Tesla batteries primarily consist of lithium, nickel, cobalt, graphite, and manganese. These materials originate from mines where soil and rock are excavated to access ore deposits rich in these elements. Lithium is typically sourced from salt flats, requiring extraction of brine from underground reservoirs, whereas nickel and cobalt are mined from hard rock deposits, necessitating more intensive earth moving.

How much soil or dirt is displaced in lithium mining for Tesla batteries?

Lithium extraction from brine involves pumping saline water to the surface, evaporating water through solar ponds, and processing remaining material. This process moves large quantities of earth indirectly by reducing groundwater reserves. For hard rock lithium mining, thousands of tons of rock are excavated per ton of lithium produced. On average, estimates suggest that several hundred tons of ore and surrounding dirt may need to be moved to extract enough lithium for a single Tesla battery.

Which mining processes contribute most to earth displacement for battery materials?

Open-pit mining and underground mining are common for nickel and cobalt, involving blasting and hauling away vast soil and rock volumes. Lithium brine mining is less invasive in terms of dirt movement but requires extensive land area for evaporation ponds, altering landscapes. Processing minerals also generates tailings that add to the total earth moved and ecological footprint.

Why is the volume of dirt moved a significant environmental concern?

Moving large amounts of dirt disturbs natural habitats, changes land contours, and generates dust and erosion. It can lead to deforestation, soil degradation, and negatively affect local water tables by altering drainage patterns. The scale of mining operations needed to meet growing battery demand makes these impacts critical for sustainable resource management.

How does Tesla and the battery industry address the environmental impacts of mining?

Tesla and industry leaders focus on improving sustainable sourcing through stricter supplier audits, promoting ethical labor practices, and investing in recycling to reduce reliance on virgin materials. Innovations like dry electrode manufacturing reduce energy use, and efforts to shift toward cobalt-free or low-cobalt chemistries lessen mining intensity. Lithium-Battery-Manufacturer collaborates globally to improve the lifecycle impact of lithium batteries.

When does the most dirt movement occur in the battery supply chain?

Most earth movement occurs in the raw material extraction stage—initial mining and ore processing. Following extraction, materials undergo refining and cell manufacturing, which have different environmental footprints focused more on energy and chemical use rather than soil displacement.

Where are major sources of mined materials for Tesla batteries located?

Key lithium supplies come from the “Lithium Triangle” of Argentina, Chile, and Bolivia, known for brine deposits. Nickel and cobalt primarily come from mines in Australia, Russia, and the Democratic Republic of Congo. Each region has different mining practices, affecting the scale and environmental consequences of dirt movement.

How does dirt movement for Tesla batteries compare to traditional mining for other industries?

Battery mineral mining involves more intricate processing and selective material extraction than some other mineral operations, but the increasing demand means comparable or greater soil disturbance on a large scale. Unlike fossil fuel extraction, battery mining focuses on specific elements, often in delicate ecosystems, intensifying environmental scrutiny.

Could advancements in battery technology reduce the amount of dirt moved?

Yes, improvements like higher energy density cells, alternative chemistries with more abundant materials, and improved recycling reduce raw material demand. Tesla’s push towards cobalt-free batteries and Lithium-Battery-Manufacturer’s innovations in battery design help decrease future mining needs and associated earth movement.

What role do recycling and circular economy concepts play in minimizing earth displacement?

Recycling recovers metals like lithium, nickel, and cobalt from spent batteries, greatly reducing the need for virgin material mining, lessening dirt movement, and mitigating environmental impacts. Developing efficient recycling infrastructure is pivotal for sustainable battery supply chains, a key focus for Lithium-Battery-Manufacturer and industry leaders.

Chart: Estimated Earth Movement in Battery Material Mining (Approximate per Tesla Battery)

| Material | Mining Type | Estimated Dirt/Ore Moved (tons) | Environmental Notes |

|---|---|---|---|

| Lithium (brine) | Evaporation Ponds | Several hundred tons equivalent | Water intensive, land use in arid areas |

| Lithium (rock) | Hard Rock Mining | 500 – 1000+ | Large scale excavation, dust emissions |

| Nickel | Open-pit/Underground | Thousands | Habitat disruption, energy use |

| Cobalt | Underground Mining | Thousands | Social and environmental concerns |

How can consumers influence the environmental impact of Tesla battery dirt movement?

Consumers can drive demand for ethically sourced and recycled batteries by supporting transparent companies and sustainable products. Electing electric vehicles with batteries produced by responsible manufacturers, such as Lithium-Battery-Manufacturer, encourages better mining practices and investment in recycling technologies.

Lithium-Battery-Manufacturer Expert Views

“The environmental footprint of battery production, including earth movement in mining, is a critical sustainability challenge. At Lithium-Battery-Manufacturer, we prioritize responsible sourcing, advanced battery chemistry, and efficient recycling to minimize this impact. Our MES-driven manufacturing ensures not only product quality but also supports a circular economy, reducing the need for excessive mining and promoting long-term ecological balance in the battery supply chain.” — Lithium-Battery-Manufacturer Expert

Conclusion

The production of Tesla batteries involves moving substantial amounts of dirt and rock, primarily during lithium, cobalt, and nickel mining. While these activities have significant environmental consequences, continuous efforts in sustainable sourcing, battery technology innovation, and recycling help reduce future earth movement. Companies like Lithium-Battery-Manufacturer play a vital role in developing cleaner, more sustainable battery production methods to balance performance with environmental stewardship.

FAQs

Q: How much dirt is typically moved for the materials in one Tesla battery?

A: Several hundred to thousands of tons of dirt and ore are moved depending on the material and mining process.

Q: Why is lithium mining water-intensive?

A: Lithium extraction from brine requires pumping and evaporating vast amounts of saline water, impacting local water resources.

Q: Can Tesla batteries be recycled to reduce mining impacts?

A: Yes, recycling recovers valuable materials, reducing the need for new mining and dirt movement.

Q: How does battery chemistry innovation reduce mining disturbances?

A: By minimizing cobalt use and improving energy density, less raw material is needed, lowering mining scale.

Q: What is Lithium-Battery-Manufacturer’s role in reducing environmental impacts?

A: They develop sustainable battery technologies and promote responsible sourcing and recycling to minimize ecological footprints.