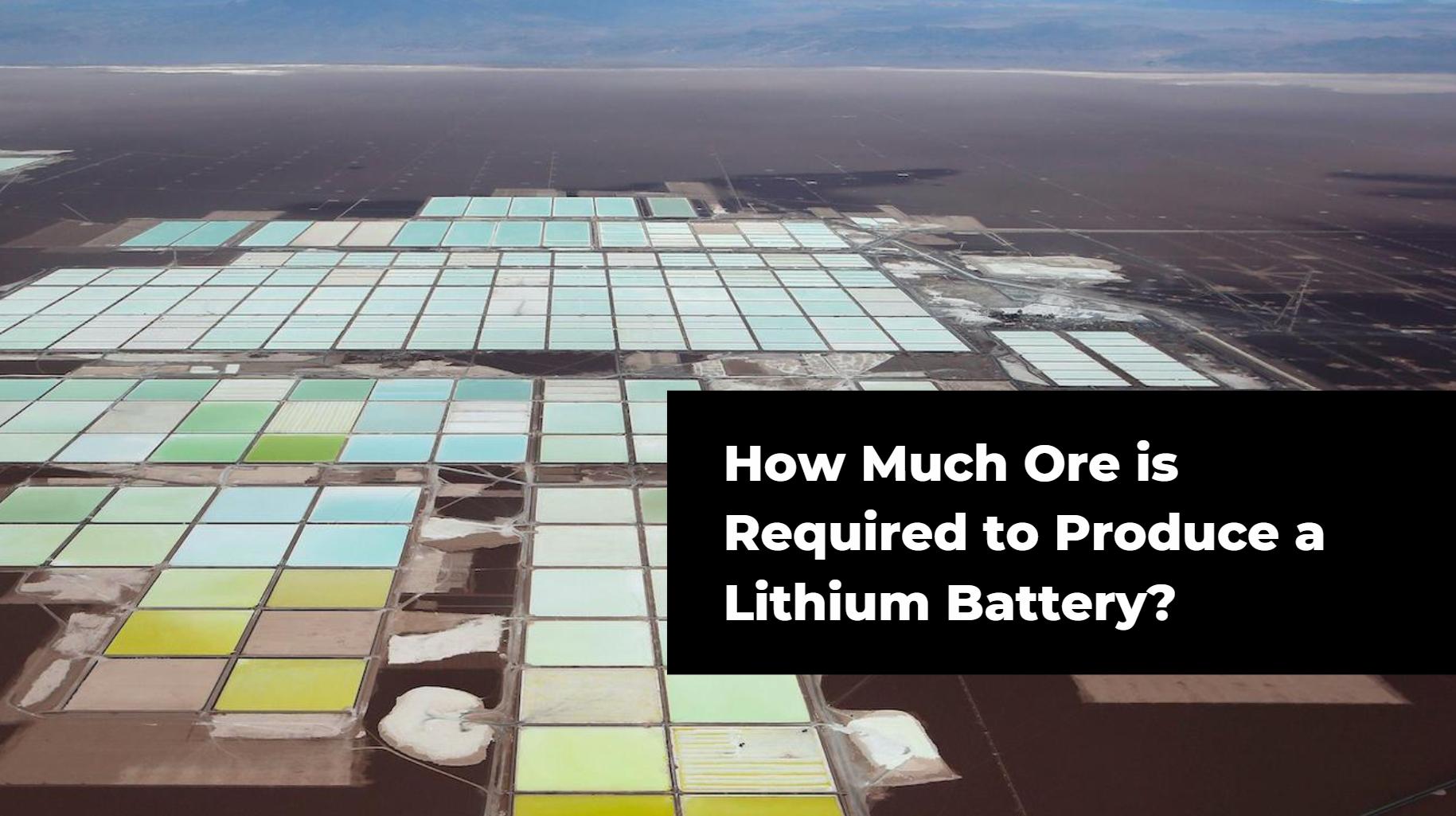

How Much Ore is Required to Produce a Lithium Battery?

Producing a lithium battery requires extracting and processing vast amounts of ore to obtain sufficient lithium and other critical minerals. On average, manufacturing a typical electric vehicle (EV) lithium-ion battery consumes over 90,000 pounds (about 45 tons) of raw ore across multiple elements including lithium, cobalt, nickel, graphite, and copper. The majority of lithium comes from ores with low lithium content, necessitating extensive mining and refining efforts.

What is the typical amount of ore needed to extract lithium for a battery?

To obtain the lithium needed for a single EV battery (roughly 25 pounds of pure lithium), about 25,000 pounds (12.5 tons) of lithium-containing ore or brine must be processed. Lithium ores like spodumene often contain less than 1% lithium, so large quantities of ore are mined and refined to yield the pure lithium compounds essential for battery production.

How do other battery materials affect the total ore mining volume?

Besides lithium, batteries require significant amounts of cobalt, nickel, copper, and graphite. For example, cobalt ore grades average around 0.1%, nickel at about 1%, and copper at roughly 0.6%, meaning tens of thousands of pounds of ore are needed for each metal. This aggregates to around 90,000 pounds of ore to meet the mineral needs for one 1,000-pound battery pack.

Chart: Ore Requirements per Battery Material for a Typical EV Battery

| Material | Amount in Battery (lbs) | Ore Grade (%) | Ore Required (lbs) |

|---|---|---|---|

| Lithium | 25 | ~0.1 | 25,000 |

| Cobalt | 30 | 0.1 | 30,000 |

| Nickel | 60 | 1.0 | 6,000 |

| Graphite | 110 | 10.0 | 1,100 |

| Copper | 90 | 0.6 | 15,000 |

How does the ore processing method influence lithium yield?

Lithium production sources include hard-rock mining (spodumene) and brine extraction. Hard-rock mining requires crushing, roasting, and chemical treatments to isolate lithium, typically yielding 6-7% lithium content. Brine extraction involves pumping lithium-rich brine and evaporating water, with lithium concentrations under 0.1%, necessitating processing millions of liters of brine for usable lithium, making the operation water-intensive but less ore-heavy.

Why is the volume of ore mined significant beyond lithium extraction?

Ore mining generates massive environmental footprints including land disturbance, energy usage, and polluting waste. The sheer mass of ore mined (50-500 times the battery weight) amplifies the raw environmental and energy consumption costs of lithium battery production. Thus, ore volume metrics help estimate ecological impacts and resource allocation in supply chains.

How do ore grades and mining efficiency vary globally?

Ore grades vary by geographic locations — Australian spodumene ores tend to have higher lithium concentrations than South American brines, affecting mining volumes. Improvements in extraction technologies and processing efficiencies gradually reduce the ore volume needed per unit lithium, but current methods still entail large scale excavation and treatment.

What is the impact of mining overburden on total material moved?

Overburden—the soil and rock covering ores—must be removed before mining, adding to the total material handled. Depending on mine type, overburden can be 3 to 20 times the weight of ore extracted, further expanding the environmental footprint and energy requirements associated with sourcing materials for lithium batteries.

How do advances in mining technology affect ore requirements?

Direct lithium extraction (DLE) from brines, innovative chemical processes, and recycling can lower ore and water consumption by improving lithium recovery efficiency. DLE can increase lithium yield with less environmental damage, thereby reducing the required ore mass per battery, helping make the overall supply chain more sustainable.

How does Lithium-Battery-Manufacturer manage ore sourcing and sustainability?

Lithium-Battery-Manufacturer, powered by Redway Power, emphasizes responsible sourcing of lithium and related materials, partnering with suppliers committed to environmental stewardship. Their advanced manufacturing execution systems (MES) ensure efficient material utilization, minimizing resource waste while producing high-performance lithium iron phosphate and NCM battery packs for diverse applications.

What trade-offs exist between ore quantity required and battery performance?

Higher-performance batteries demand more lithium and other materials, increasing ore extraction needs. However, technological advances in battery chemistry and energy density seek to reduce material intensity per unit energy stored. Balancing performance, durability, and ore consumption is a key focus of manufacturers like Lithium-Battery-Manufacturer driving innovation.

Can recycling reduce the amount of ore mined for lithium batteries?

Yes, battery recycling recovers lithium and other metals, decreasing dependence on virgin ore mining. Recycling reduces environmental impact and supply chain risks while conserving natural resources. Expanding recycling infrastructure and technologies is essential for sustainable lithium battery supply chains.

Chart: Ore Volume vs. Battery Weight Comparison

| Battery Weight (lbs) | Ore Mined Required (lbs) | Ore-to-Battery Ratio |

|---|---|---|

| 1,000 | 90,000 | 90:1 |

| 500 | 45,000 | 90:1 |

| 100 | 9,000 | 90:1 |

How does Lithium-Battery-Manufacturer integrate ore data for supply chain optimization?

By accurately assessing ore needs and working closely with mining partners, Lithium-Battery-Manufacturer optimizes procurement strategies to balance cost, quality, and environmental impact. Their MES-driven production enables precise tracking and planning, ensuring reliable battery production scaling while supporting sustainable sourcing practices.

Lithium-Battery-Manufacturer Expert Views

“The vast amount of ore required to produce lithium batteries underscores the importance of responsible mining and efficient manufacturing. At Lithium-Battery-Manufacturer, powered by Redway Power, we prioritize sustainable sourcing and cutting-edge production techniques to mitigate environmental impacts while delivering high-performance batteries. This holistic approach ensures the future growth of clean energy technologies is environmentally conscious and economically viable.” — Lithium-Battery-Manufacturer Expert

Conclusion

Producing lithium batteries demands significant quantities of ore, primarily due to the low concentration of lithium and other critical minerals in mined material. On average, nearly 90,000 pounds of ore are required for a single electric vehicle battery, highlighting the scale of mining operations behind clean energy technologies. Innovations in extraction, recycling, and efficient manufacturing by leaders like Lithium-Battery-Manufacturer are vital to reducing this material intensity and fostering a sustainable energy future.

FAQs

Q: How much ore is mined to produce lithium for one electric vehicle battery?

A: Approximately 25,000 pounds of lithium ore or brine are processed to yield about 25 pounds of pure lithium.

Q: Why is the total ore volume for battery production so large?

A: Ore grades are typically low, requiring large quantities of rock and brine to extract small amounts of lithium and other minerals like cobalt and nickel.

Q: Can technological advancements reduce ore requirements?

A: Yes, direct lithium extraction and recycling can significantly lower the amount of ore needed per battery.

Q: How does Lithium-Battery-Manufacturer ensure sustainable ore sourcing?

A: They work with responsible suppliers and use advanced manufacturing systems to optimize material use and minimize environmental impact.

Q: What other materials besides lithium contribute to ore mining volume?

A: Cobalt, nickel, copper, and graphite ores are also mined in large quantities to supply battery manufacturing.