Description

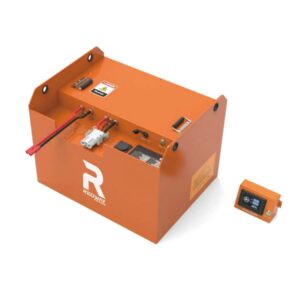

Our 36V 700Ah LiFePO4 Forklift Battery is engineered for heavy-duty industrial operations, combining high energy density with unmatched durability. As a leading lithium battery manufacturer, we specialize in OEM solutions that deliver superior performance, extended lifespan, and reduced operational costs for material handling fleets.

Key Features

High-Capacity Powerhouse: 36V/700Ah configuration provides 25.2 kWh energy output, supporting uninterrupted operation for up to 18 hours under full load.

Rapid Discharge Capability: Handles 320A continuous and 480A peak discharge (5-second bursts) for demanding lifting and transportation tasks.

Ultra-Long Cycle Life: 4,000+ cycles at 80% depth of discharge (DOD), outperforming lead-acid batteries by 3x lifespan with minimal capacity degradation.

Rugged Design: IP65-rated enclosure and reinforced metal shell ensure dustproof, waterproof, and shock-resistant performance in harsh environments.

Smart BMS Integration: Advanced 4G-enabled Battery Management System monitors SOC, temperature, and voltage in real time, preventing overcharge, overcurrent, and thermal risks.

Product Description

Designed for OEM and wholesale buyers, our 36V 700Ah LiFePO4 Forklift Battery optimizes warehouse logistics with fast charging (0-100% in 2.5 hours) and modular dimensions (967 x 515 x 779 mm). The lithium battery¡¯s lightweight 330 kg design reduces forklift energy consumption while maintaining compatibility with Class I-III equipment. Proprietary cell-balancing technology ensures <3% annual capacity loss, backed by a 5-year warranty for long-term reliability.

How to Maintain 36V 700Ah Lithium-Ion Forklift Batteries Efficiently?

Clean terminals monthly and store batteries in dry, 50¡ãF¨C77¡ãF environments. Avoid deep discharges below 20% SOC and use BMS data to schedule preventive maintenance.

Longevity Benefits vs. Lead-Acid Batteries

The 36V 700Ah lithium battery achieves 5,000+ cycles with 80% capacity retention, eliminating frequent replacements. It operates at 95% efficiency versus 70% for lead-acid models, reducing energy waste.

Safety Features for Industrial Use

Multi-layer safeguards include flame-retardant casing, short-circuit protection, and temperature-controlled charging. The BMS automatically isolates faulty cells to prevent system failures.

Charging Optimization Strategies

Utilize opportunity charging during breaks and avoid extreme temperatures. Compatible 1C fast chargers restore 80% capacity in 90 minutes without compromising battery health.

By prioritizing innovation and OEM customization, our lithium battery solutions empower businesses to achieve higher productivity, lower TCO, and sustainable operations.

700Ah Lithium Forklift Battery Specifications and Performance

What is the voltage and capacity of the battery?

The 700Ah lithium forklift battery typically operates at a nominal voltage of 36V and has a capacity of 700Ah. This configuration provides high energy output, suitable for heavy-duty forklifts used in industrial settings. The large capacity allows for extended operation times, reducing downtime between charges and supporting demanding tasks in warehouses or factories.

Which heavy-duty applications suit this forklift battery?

The 700Ah lithium forklift battery is ideal for heavy-duty applications such as large warehouses, distribution centers, and manufacturing plants. It powers industrial forklifts, pallet jacks, and reach trucks used for transporting heavy loads over long periods. Its high capacity and durability make it perfect for continuous operations in high-demand environments.

How does lithium technology improve forklift battery performance?

Lithium technology enhances forklift battery performance by providing longer lifespan, faster charging, and consistent power output. Lithium-ion batteries have a higher energy density than traditional lead-acid batteries, meaning they last longer and can handle deeper discharges. These batteries also charge quicker and require less maintenance, improving overall operational efficiency.

What is the lifespan of a 700Ah lithium forklift battery?

The 700Ah lithium forklift battery typically lasts between 4,000 to 6,000 charge cycles or around 7-10 years of regular use. This extended lifespan is significantly longer than traditional lead-acid batteries, which may need replacement every 2-3 years. Proper care and maintenance can maximize the lifespan of lithium forklift batteries.

What safety features support industrial environments?

Safety features in the 700Ah lithium forklift battery include a Battery Management System (BMS), thermal protection, and overcharge prevention. The BMS ensures safe charging and discharging, while thermal protection prevents overheating. These features, along with fire-resistant casing, make lithium forklift batteries suitable for demanding and high-risk industrial environments.

Are there specific maintenance requirements for this battery?

The 700Ah lithium forklift battery requires minimal maintenance, mainly focusing on periodic cleaning of terminals, regular checks of battery voltage, and ensuring proper ventilation during charging. Additionally, avoid deep discharges and follow recommended charging cycles to maximize battery lifespan. No water refilling is required, unlike lead-acid batteries.

Chinese Manufacturers and Lithium Battery Innovations

Who are the top lithium battery forklift makers in China?

Top Chinese manufacturers of lithium forklift batteries include BYD, CATL, Gotion High-Tech, and Sungrow Power Supply. These companies lead the market with advanced battery technologies, offering high-performance, durable, and cost-effective solutions for industrial applications worldwide. They are known for their substantial investments in R&D and production capabilities.

What technologies set leading Chinese manufacturers apart?

Leading Chinese lithium forklift battery manufacturers stand out with technologies like advanced Battery Management Systems (BMS), fast charging capabilities, and high-energy density cells. These innovations enhance battery efficiency, safety, and overall performance. Additionally, Chinese manufacturers focus on cost-reduction technologies to offer competitive pricing without compromising quality.

Which companies dominate China’s lithium forklift battery market?

BYD, CATL, and Gotion High-Tech are the dominant players in China’s lithium forklift battery market. These companies have a significant share of both domestic and international markets, owing to their high-quality production, cutting-edge technologies, and global supply chains. They are recognized for their commitment to sustainable energy solutions.

How do Chinese firms influence global lithium forklift markets?

Chinese firms like BYD and CATL play a major role in shaping global lithium forklift battery markets by driving down costs, introducing innovative technologies, and expanding production capacity. Their products are exported worldwide, providing cost-effective alternatives to traditional lead-acid batteries, and helping industrial operations achieve higher efficiency.

What innovations drive Chinese lithium forklift battery development?

Innovations driving Chinese lithium forklift battery development include fast charging technology, higher energy densities, and improved safety features such as thermal management and overcharge protection. These advancements enable batteries to perform better in demanding environments, reduce downtime, and enhance the cost-effectiveness of forklift operations.

What trends shape China’s lithium battery forklift industry growth?

The growth of China’s lithium forklift battery industry is shaped by trends such as sustainability initiatives, advances in charging technology, and growing demand for electric vehicles. Additionally, as companies seek cost-effective energy solutions, the demand for lithium batteries continues to increase, fostering innovation and expanding the market for industrial applications.

700Ah Lithium Battery Pricing, Discounts, and Cost Performance

What factors influence 700Ah lithium battery pricing?

The pricing of 700Ah lithium forklift batteries is influenced by factors such as material costs (lithium, cobalt, nickel), battery technology, manufacturing scale, and supplier certifications. Other factors include the cost of Battery Management Systems (BMS), safety features, and charging technologies. Geographical location and shipping fees also play a role.

How do 700Ah battery prices vary by region?

700Ah lithium battery prices vary by region due to local manufacturing costs, material availability, and shipping fees. In regions with large-scale production facilities like China, prices tend to be lower due to efficient production. However, transportation costs and tariffs in other regions like Europe or North America can increase overall pricing.

Compare 700Ah lithium battery prices by brand

The price of 700Ah lithium forklift batteries varies by brand. BYD and CATL typically offer higher prices due to their advanced technology, strong brand recognition, and global distribution networks. In comparison, local brands in China may offer more competitive pricing, though quality and performance can vary. Always compare prices and features.

Price trends for 700Ah lithium batteries over time

The price of 700Ah lithium forklift batteries has steadily declined over the years due to improved manufacturing efficiency, advances in technology, and the rising supply of raw materials like lithium. Prices have become more affordable as demand for electric forklifts increases, and competition among suppliers grows, especially in China.

Are bulk purchase discounts available for 700Ah batteries?

Yes, bulk purchase discounts are often available for 700Ah lithium forklift batteries. Suppliers typically offer volume-based pricing reductions for larger orders. These discounts can be particularly beneficial for businesses that need multiple units for their fleet, reducing the per-unit cost and increasing overall value for large-scale operations.

Which 700Ah lithium batteries offer best cost-performance ratio?

The best cost-performance ratio for 700Ah lithium batteries typically comes from reputable Chinese brands like BYD and CATL. These manufacturers offer high-performance batteries with competitive pricing, backed by advanced technologies like fast charging and long lifespans. It’s important to compare features like battery management, warranty, and after-sales support to determine the best value.

Fast Charging and Safety Features for 700Ah Lithium Batteries

What is 36V lithium battery fast charging technology?

36V lithium battery fast charging technology allows forklifts and industrial vehicles to charge their batteries at a significantly higher rate than conventional chargers. This technology typically uses higher current and advanced cooling systems to prevent overheating, enabling a fully charged battery in 2-4 hours, depending on battery capacity and charger specifications.

How does fast charging work for 36V lithium batteries?

Fast charging for 36V lithium batteries works by using high-current charging that can charge a battery at a rate up to 2-3 times faster than standard charging methods. Specialized chargers, coupled with thermal management systems, prevent overheating and ensure the battery’s safety while allowing for quick turnarounds in operations.

What are the advantages of long-lasting 36V lithium batteries?

The main advantage of long-lasting 36V lithium batteries is their extended operational life, typically lasting 3-5 times longer than traditional lead-acid batteries. This reduces the need for frequent replacements and lowers overall operating costs. Additionally, they offer faster charging, improved energy efficiency, and reduced maintenance requirements, contributing to higher productivity.

Are 36V lithium batteries safe during fast charging?

Yes, 36V lithium batteries are safe during fast charging if equipped with proper Battery Management Systems (BMS) and thermal protection. These safety features ensure that the battery does not overheat or become damaged during the charging process. Fast chargers also use current regulation to prevent excessive power from damaging the battery, ensuring safe operation.

What applications use 36V fast-charging lithium batteries?

Applications that use 36V fast-charging lithium batteries include forklifts, electric pallet trucks, material handling equipment, and automated guided vehicles (AGVs). These batteries are ideal for high-demand environments where minimal downtime is critical, such as in warehouses, logistics centers, and distribution facilities. Fast charging ensures quick recovery between shifts.

How to maintain 36V lithium batteries for optimal lifespan?

To maintain 36V lithium batteries for optimal lifespan, avoid deep discharges and ensure the battery is regularly charged to 100%. Store batteries in a cool, dry environment and ensure proper ventilation during charging. Regularly check for signs of corrosion or damage to terminals, and keep the battery clean for optimal performance.

Safety Standards and Risk Management for 700Ah Lithium Forklift Batteries

What safety standards apply to 700Ah lithium forklift batteries?

700Ah lithium forklift batteries must comply with international safety standards such as UN38.3 for transportation, UL 2054 for electrical safety, and CE for European compliance. These standards ensure that the batteries are safe for industrial use and meet safety requirements for manufacturing, handling, and disposal.

How does 700Ah capacity impact lithium forklift battery safety?

A 700Ah lithium forklift battery, with its high capacity, requires more robust safety systems such as thermal management and overcharge protection. Higher capacities demand more advanced Battery Management Systems (BMS) to prevent overcharging, short circuits, or thermal runaway, ensuring safe operation in demanding environments.

What are common safety risks in 700Ah lithium forklift batteries?

Common safety risks in 700Ah lithium forklift batteries include overheating, overcharging, and thermal runaway. To mitigate these risks, batteries are equipped with Battery Management Systems (BMS), temperature sensors, and protection circuits to monitor and regulate charging and discharging. Regular maintenance and proper handling are essential to avoid these hazards.

How do lithium forklift batteries prevent thermal runaway at 700Ah?

Lithium forklift batteries, including 700Ah models, prevent thermal runaway through advanced temperature sensors and thermal management systems that monitor the battery’s temperature. If the temperature exceeds a safe limit, the BMS will automatically reduce charging current or disconnect the battery to prevent overheating and potential hazards.

What maintenance ensures safety for 700Ah lithium forklift batteries?

Maintaining safety for 700Ah lithium forklift batteries includes regular inspection of terminals, monitoring voltage levels, and ensuring proper ventilation during charging. Additionally, ensure the battery is not exposed to extreme temperatures and avoid deep discharges. Routine checks of the Battery Management System (BMS) ensure the system functions properly.

Are 700Ah lithium forklift batteries safer than lead-acid alternatives?

Yes, 700Ah lithium forklift batteries are generally safer than lead-acid alternatives. They are less prone to leakage, do not require regular maintenance such as water refilling, and have advanced safety mechanisms like overcharge protection and thermal management. Lithium batteries also have a significantly lower risk of explosion or corrosion.