Description

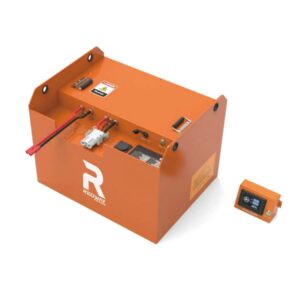

Our 48V 460Ah LiFePO4 Forklift Battery is engineered for industrial efficiency and durability. As a professional lithium battery manufacturer, we specialize in OEM solutions that deliver unmatched energy density, safety, and cost savings for material handling operations.

Key Features

High-Energy Performance: 48V/460Ah design provides 23.68 kWh of power, supporting extended shifts in warehouses and logistics centers.

Ultra-Durable Lifespan: 6,000+ cycles at 80% DoD ensure 3x longer service than lead-acid batteries, minimizing replacement costs.

Heavy-Load Ready: Sustains 400A continuous discharge and 900A peak output for demanding lifting and transport tasks.

Smart Connectivity: Integrated 4G/CAN-bus/RS485 enables real-time monitoring of SOC, temperature, and diagnostics via cloud platforms.

All-Weather Reliability: IP65-rated metal housing protects against dust, moisture, and vibrations in -20¡ãC to 60¡ãC environments.

Product Description

Designed for OEM and wholesale partners, our 48V 460Ah LiFePO4 Forklift Battery combines military-grade LiFePO4 cells with adaptive balancing technology to maintain <95% capacity retention after 3,000 cycles. The modular design (customizable dimensions) fits 90% of Class I-IV forklifts without structural modifications.

Proprietary phase-change cooling ensures stable operation during rapid charging (0-100% in 2 hours). The multi-layered BMS prevents overcharge, short circuits, and thermal runaway while enabling remote firmware updates. Custom branding, flexible shipping terms (FOB/EXW/CIF), and a 7-year warranty make this lithium battery ideal for global supply chains.

How Does a 48V 460Ah Lithium Forklift Battery Enhance Efficiency?

A 48V 460Ah lithium forklift battery delivers 23.55 kWh of reliable power, offering longer runtime, rapid charging, and advanced safety features. Its lightweight design and intelligent BMS improve forklift efficiency, reduce downtime, and lower operational costs in demanding industrial environments.

What are the key specifications of a 48V 460Ah lithium forklift battery?

This battery features a nominal voltage of 51.2V and a capacity of 460Ah, providing 23.55 kWh of energy. Dimensions typically measure around 950 x 421 x 450 mm, weighing approximately 190 kg. It supports continuous discharge currents up to 300A and peak currents of 1000A for short bursts. The battery has a robust metal casing with an IP67 rating. Communication protocols include RS485, CAN bus, and 4G connectivity.

How long can a 48V 460Ah lithium forklift battery last on a single charge?

Under moderate load, this battery can power forklifts for 8 to 12 hours. For example, at a continuous 50A draw, it provides approximately 9.2 hours of runtime (460Ah ÷ 50A).

What advantages do lithium forklift batteries offer over traditional lead-acid batteries?

Lithium batteries provide faster charging (1.5 to 3 hours vs. 8 hours), longer cycle life (3500+ cycles vs. 1000-1500), lighter weight (about 40% less), zero maintenance, higher energy efficiency (up to 99%), and consistent voltage output, reducing downtime and operational costs.

How long is the typical lifespan and cycle life of a 48V 460Ah lithium forklift battery?

These batteries typically offer over 3500 charge cycles at 80% depth of discharge, translating to 7-10 years of reliable service.

How fast can a 48V 460Ah lithium forklift battery be charged?

With compatible chargers, full charging takes approximately 1.5 to 3 hours, enabling multi-shift operations without long downtime.

What safety features are integrated into lithium forklift batteries?

Advanced BMS systems protect against overcharge, over-discharge, short circuit, overcurrent, and temperature extremes. Thermal management and cell balancing enhance safety and longevity.

What applications are best suited for 48V 460Ah lithium forklift batteries?

Ideal for heavy-duty forklifts, reach trucks, pallet jacks, and warehouse equipment, these batteries improve operational efficiency in logistics, manufacturing, and distribution centers.

What environmental conditions can a 48V 460Ah lithium forklift battery withstand?

Designed for industrial use, these batteries operate reliably between -20°C and 60°C and feature IP67-rated enclosures protecting against dust and water ingress.

How does the lighter weight of lithium batteries impact forklift operations?

Reduced battery weight improves forklift maneuverability, decreases floor wear, facilitates easier battery handling, and contributes to overall energy efficiency.

What communication protocols support battery monitoring and management?

Protocols like RS485, CAN bus, and 4G enable real-time monitoring, predictive maintenance, and integration with fleet management systems.

How does lithium battery technology improve overall forklift efficiency?

Lithium batteries provide consistent power delivery, reduce charging downtime, extend battery lifespan, and lower maintenance, resulting in increased uptime and lower total cost of ownership.

Chart 1: Lithium vs. Lead-Acid Forklift Battery Comparison

| Feature | Lithium (48V 460Ah) | Lead-Acid (48V 460Ah) |

|---|---|---|

| Cycle Life (Cycles) | 3500+ | 1000-1500 |

| Charge Time (Hours) | 1.5 – 3 | 8 |

| Weight (kg) | 190 | 300-400 |

| Maintenance | None | Regular watering |

| Efficiency (%) | Up to 99 | ~80 |

Chart 2: Operating Temperature and Environmental Protection

| Feature | Specification | Benefit |

|---|---|---|

| Operating Temp. | -20°C to 60°C | Reliable in industrial environments |

| IP Rating | IP67 | Dust and water resistant |